Smart Factories, Smarter Business: The Future of Manufacturing in Australia

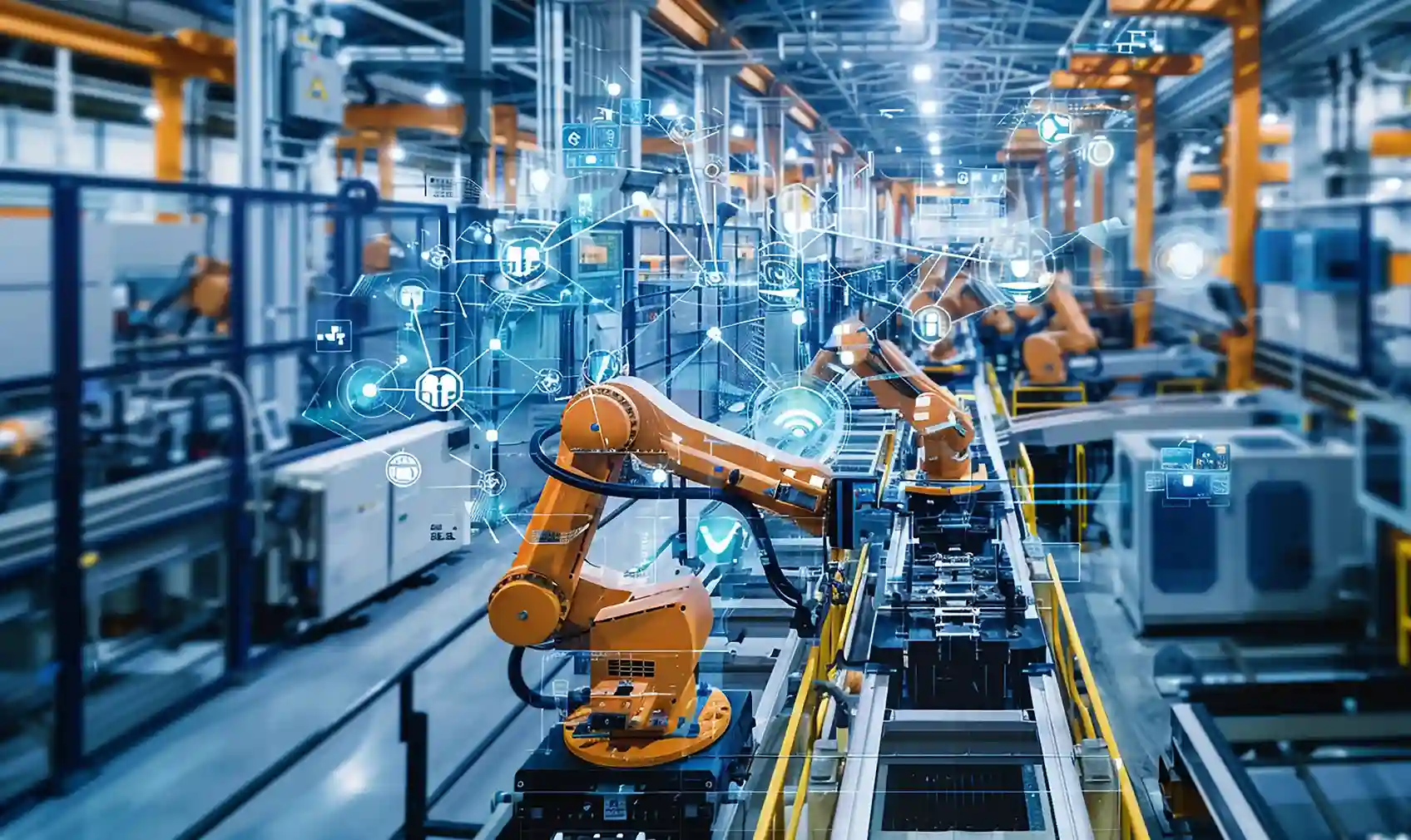

Manufacturing has transformed from concentrating on machines performing tasks to a business where systems think, adapt, and evolve. Smart factories are transforming production floors into intelligent, interconnected ecosystems where robotics, AI, and data analytics collaborate effectively.

This fresh chapter in manufacturing extends beyond just the big corporations and elite industrial players. For small and medium businesses aiming to remain competitive, efficient, and adaptable, this is increasingly a natural development.

By 2026, the evolution of smart manufacturing will determine the success of businesses, differentiating those that succeed from those falling behind. The good news? It’s now easier to achieve—and more fulfilling—than it has ever been.

Why Smart Manufacturing Matters Now

Manufacturers are facing a growing number of challenges: shortages of workers, increasing operational expenses, vulnerable supply chains, and ever-changing consumer preferences. Traditional systems just can’t match the speed of today’s demands.

Innovative changes in manufacturing transform that. By integrating technology with production, companies have the ability to make quicker, informed decisions, improve performance, and increase profitability.

Smart factories use real-time data to observe, anticipate, and react to all activities happening on the manufacturing floor. They have the ability to spot maintenance problems before they stop production, modify schedules in response to supply chain interruptions, and anticipate customer demand ahead of order arrival.

Rockwell Automation discovered that more than 50% of local manufacturers intend to enhance their use of smart technologies by 2026, aiming to boost both efficiency and durability. The transition is occurring rapidly, and those who adopt it quickly will lead the next industrial revolution.

For business owners—whether you operate a local workshop or manage a successful manufacturing facility—embracing smart manufacturing has become crucial. It’s a tactic for overcoming challenges.

Key Technologies Shaping Smart Manufacturing

At the core of smart manufacturing is a blend of cutting-edge technologies that collaborate effortlessly. These tools are increasingly easy to access, user-friendly, and budget-friendly, allowing every business to work more efficiently.

Robotics and Automation

modern robotics extend well beyond the limits of heavy industrial arms. Collaborative robots, commonly known as cobots, are now designed to work alongside humans, taking on repetitive tasks with safety and efficiency in mind.

They improve productivity, enabling team members to concentrate on innovative and analytical tasks. With automation, production lines can run continuously, leading to reduced costs, improved precision, and higher quality.

As noted by Rockwell Automation, adaptive robotics will soon dominate manufacturing environments, learning and adjusting autonomously in real time.

Artificial Intelligence and Predictive Analytics

The smart factory relies on AI as its central intelligence. This method examines data throughout operations—anticipating demand, pinpointing quality concerns, and forecasting maintenance requirements before any failures happen.

This level of insight enables companies to minimize downtime, save resources, and maintain speed.

ITBrief focuses on the transformative power of AI systems, enabling businesses to make quick, data-driven decisions that previously required entire departments—now done in just a few minutes.

Internet of Things (IoT) and Digital Twins

IoT sensors easily connect machinery, systems, and processes into an integrated network. Each device contributes data to a digital twin, creating a virtual representation of the actual factory.

This allows business owners to experiment, evaluate, and improve their operations securely prior to implementing changes in production.

As stated by MYOB, digital twins are transforming planning and maintenance, providing manufacturers with unmatched authority and visibility.

Automated Safety and Worker Empowerment

Smart factories go beyond just efficiency; they enhance safety as well. Instantly detecting potential hazards, sensors and machine-learning algorithms work in together, while connected systems independently shut down or alert teams as needed. At the same time, employees acquire resources that enable them to concentrate on advanced decision-making and encouraging innovation.

Automation enables teams to enhance their efficiency and productivity.

Why Small and Medium Businesses Should Care (and Soon)

Once upon a time, the idea of digital transformation seemed costly and impossible to reach. That is no longer the case. Modern smart manufacturing solutions are flexible, cost-effective, and built to grow alongside your business.

Here’s why small and medium enterprises (SMEs) need to pay attention:

It’s More Accessible Than Ever

With the rise of cloud platforms and subscription-based technologies, initial costs have significantly decreased, allowing even small-scale operators to access smart tools.

Measurable Benefits for Your Investment

Automation minimizes waste, cuts down on downtime, and improves employee productivity. A small improvement in uptime can lead to huge annual savings, potentially reaching to thousands..

Greater Resilience

Smart factories have the ability to quickly adjust to changes in the supply chain or workforce dynamics. Predictive systems play a crucial role in maintaining business continuity despite changing external factors.

Workforce Appeal

Modern, technologically advanced workplaces draw in younger professionals who prioritize innovation and cutting-edge systems.

Industry Partners highlights that small manufacturers who embrace automation early are “opening the way for the next chapter of industrial growth.” In other terms, hesitation might turn out to be the priciest choice you ever make..

Step by Step: The Road to Smart Factory

Shifting to a smart factory can be achieved without needing a complete transformation. It’s all about taking steady, actionable steps that lead to results smoothly and effectively.

Step 1: Begin with a Focus Area

Begin with the basics. Select a specific production process, such as quality monitoring or packaging, and present an automation tool or sensor system that can enhance its efficiency. Initial successes create a sense of progress and boost confidence.

Step 2: Collect and Understand Data

Data serves as the foundation of intelligent manufacturing. Use IoT sensors and analytics tools to capture immediate insights on energy consumption, operational downtime, and throughput efficiency.

Step 3: Train and Empower Your Team

Enhancing your skills is crucial. Empower your team to grasp and utilize new systems with confidence. When individuals view technology as a partner, the process of adoption becomes quicker and more simple.

Step 4: Integrate Gradually

Connect your digital systems progressively—starting with AI forecasting, then integrating robotics, safety sensors, and ERP tools. This seamless integration minimizes interruptions while optimizing returns.

Step 5: Monitor, Measure, Improve

Set precise KPIs for your transformation journey—production speed, energy efficiency, waste reduction. Consistently evaluate and enhance your strategy based on the results.

As your operations grow more connected and streamlined, an additional benefit develops that goes beyond just productivity and cost efficiency, which is sustainability.

Sustainability: The Smarter Business Advantage

Sustainability has evolved beyond just an ethical concern; it has become a crucial factor in gaining a competitive edge. Smart factories naturally consume fewer resources and function with enhanced efficiency, leading to lower costs and a smaller environmental footprint.

AI-driven monitoring detects energy waste, records emissions, and optimizes processes in real time. Smart technologies also support recycling activities and responsible resource use across production lines.

As Corematic (2025) explains, smart manufacturing is “central to creating cleaner, more sustainable, and more efficient production systems.”

Customers increasingly prefer to partner with businesses that demonstrate environmental responsibility. By adopting smart technologies, you’re not only saving money—you’re building brand trust and future-proofing your reputation.

Bringing Today’s Tools with Tomorrow Factories

Transforming into a smart factory isn’t something you have to do alone—having the right technology partner makes all the difference.

At ICTechnology, we see the smart factory not as a destination—but a journey. And that journey begins with connection.

Our team work with manufacturing businesses to integrate practical, scalable technologies that deliver measurable results. From IoT deployment and AI forecasting to automated safety solutions, our mission is to make digital transformation achievable—not overwhelming.

Here’s how we help:

- Assessment & Roadmap: We identify your strengths, challenges, and opportunities for smart transformation.

- Technology Integration: We implement connected tools, robotics, and data systems tailored to your scale and budget.

- Training & Enablement: We upskill your team so they can adapt confidently and thrive in a smart environment.

- Support & Scalability: As your business grows, we keep your systems evolving with it.

Smart manufacturing bridges what’s possible and what’s practical. ICTechnology is that bridge.

As innovation accelerates and competition tightens, partnering with a team that understands technology, people, and process can redefine how your business operates. The next industrial leap starts with today’s decisions.

Smart Factories for the Future

By 2026, manufacturing will look dramatically different. Factories will self-optimise, supply chains will communicate in real time, and data will power decisions across every level of business.

Machines won’t just work—they’ll collaborate. People won’t just operate—they’ll innovate.

For small and medium businesses, the opportunity is enormous. Smart factories are the key to resilience, sustainability, and growth in an increasingly digital economy.

The question is: will you be ready to lead the change—or follow it?

At ICTechnology, we’re ready to help you take that step. Let’s build smarter factories, and smarter businesses, together.

Interested in a Quote and Consultation? Reach out to:

[email protected]

Need Support on Smart Manufacturing? Please reach out!

[email protected]

Any other enquiries?

Fill out our Contact Form here.

References

Corematic. (2025, July 9). A future roadmap to advanced manufacturing in Australia. Retrieved from https://corematic.com.au/blog/a-future-roadmap-to-advanced-manufacturing-in-australia/

Industry Partners. (2025, June 23). The rise of smart manufacturing down under. Retrieved from https://www.industrypartners.com.au/blog/the-rise-of-smart-manufacturing-down-under

ITBrief. (2025, January 9). Harnessing AI for the future of manufacturing. Retrieved from https://itbrief.com.au/story/harnessing-ai-for-the-future-of-manufacturing

MYOB. (2025, April 30). 6 manufacturing tech trends shaping the future. Retrieved from https://www.myob.com/au/blog/6-manufacturing-tech-trends-shaping-the-future/

Rockwell Automation. (2025, February 24). 5 key trends redefining smart manufacturing in 2025. Retrieved from https://www.rockwellautomation.com/en-au/company/news/blogs/smart-manufacturing-trends-2025.html